WELCOME TO MARBLECAST

We design and manufacture custom cultured marble sanitaryware including shower trays, basins and bathtubs for residential and commercial projects from our headquarters in Cape Town. We also stock a curated selection of taps, showers, mixers and bathroom accessories to complement our contemporary collections.

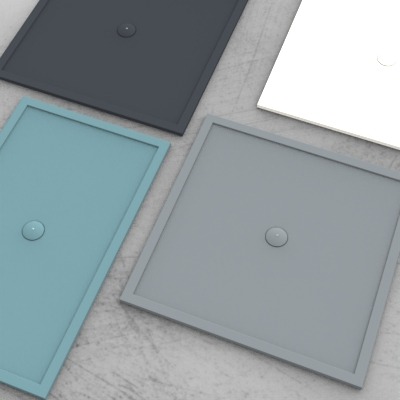

CUSTOM SHOWERS

Marblecast’s shower trays offer a durable solution that is fully customizable to your bathroom. Our cultured marble shower bases are solid, hard wearing, and resistant to cracks. As each tray is cast in one piece to your specification, they are completely watertight.

COLOURFUL BASINS

The Colour Collection is an exciting new range of cultured marble basins launched in 2020. Available in 3 shapes and 12 contemporary colours, liven up bathroom interiors with these countertop bowls that are both on-trend and durable.

BONGIO

In an exciting partnership with exclusive Italian brand Bongio, we are delighted to offer our clients a range of designer taps, mixers, showers and accessories to complement any bathroom interior.

COLLECTIONS

Marblecast's collections of cultured marble sanitaryware are designed to cater to the needs of any aesthetic or space, commercial or residential.